Cutaway Chassis: Custom Utility

Cutaway Chassis: Custom Utility

The cutaway chassis, configurable as a box van or box truck, is built for the selective business owner or fleet manager who knows what configuration is best for their use case and has time to wait for the vehicle to be built. The cutaway chassis platform, including options like the Chevrolet Express, Ford Transit and E series, and Ram ProMaster, allows you to select the body type and manufacturer that best suits your work and brand preferences. Overall, the cutaway chassis delivers a unique sense of agency when purchasing a box van or box truck.

Wheelbase

The length of a cutaway truck chassis wheelbase will determine how your finished vehicle performs. Defined as the distance between the front and rear axles, varying wheelbase measurements commonly range from 120” to 177” long across most box van models.

There are pros and cons to short and long-wheelbase options. The natural axiom is that a shorter wheelbase vehicle has a tighter turning radius and costs less, but carries less cargo. Conversely, a longer wheelbase chassis will take more room to turn around and cost more, but it can carry more (or larger) cargo.

Cab-to-Axle

The cab-to-axle (CA) dimension is the distance between the center of the rearmost axle of a vehicle to the rear of the cab. Though the cutaway chassis is a fairly straightforward vehicle model, this distance varies with the total length of the aftermarket upfit. When selecting the body to add to your cutaway chassis vehicle, identifying common CA lengths should be your first stop.

Common CA measurements for the cutaway chassis include 80”, 82.8”, 100”, 100.3” 118”, and 122.6”. As these lengths increase, the available cargo space in a cutaway upfit follows suit. Take the time to consider the amount and size of products and materials you anticipate handling and choose chassis length accordingly.

Click Here for More Information

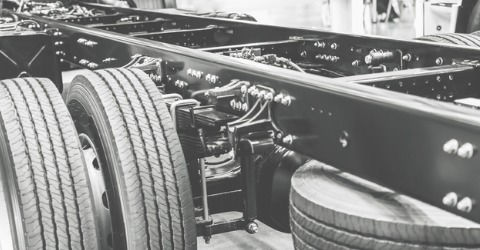

Rear Wheels

A single-rear-wheel and dual-rear-wheel configuration in a cutaway chassis provide varying operational benefits when compared against one another. Cutaway chassis owners enjoy a reduced impact on fuel efficiency in their single-rear-wheel models. Added weight from an upfit, as well as products and materials, will slightly impact fuel efficiency, but the average gas mileage of the single-rear-wheel model is higher than its dual-rear-wheel counterpart.

The dual-rear-wheel cutaway chassis configuration, while less fuel-efficient, provides far more stability and security in its additional weight distribution. The additional wheels increase payload capacity and allow more product to be carried, resulting in fewer deliveries. Each upfit in the cutaway chassis will determine how much a chassis can efficiently carry, but the overall benefit of delivering heavier loads and making fewer deliveries makes the dual-rear-wheel configuration an optimal choice.

Fuel Type

As with most commercial vehicles, box trucks and vans are available in gas, diesel, flex-fuel, and alt-fuel variations such as propane, BEV, and HEV. That said, each fuel type features a variety of benefits outside of broad geographic availability due to popular demand.

Gas-powered box truck models provide a fair middle ground in the discussion of fuel efficiency vs fuel cost. Though diesel offers more miles per gallon of fuel, the price of gasoline is significantly lower on average.

Diesel shares a marked similarity in fuel availability with gasoline with a few other added benefits. The most notable aspect of diesel engines is the enhanced hauling and towing capacity across comparable gas-powered models. Though diesel does cost more at the pump, diesel box trucks enjoy increased towing capacity, fuel efficiency, and longevity.

Towing

As a standard, the cutaway chassis is renowned for hauling and delivering products and materials to their destinations. That said, the cutaway chassis is often overlooked in its capacity for towing. With an average towing capacity between 7,500lbs and 10,000lbs, the cutaway chassis boasts further functionality outside of solely hauling materials. The cutaway chassis is an ideal candidate in cases where both product delivery and towing are required.

Comfort Level

Trim packages in a cutaway chassis make all the difference in the presentation of your business as well as the comfort of your team. Your crew will appreciate your decision to explore the custom van or truck trim packages offered by cutaway chassis manufacturers for a few reasons. These trim package levels vary among manufacturers, but larger seating sizes, upgraded dashboard modules, and a more spacious cab can be expected in both the mid-and high-end trim packages.

UPDATED ON: JANUARY 12, 2025

Published on: January 02, 2019 The Cost Benefits of Propane Autogas for Commercial Fleets

The Cost Benefits of Propane Autogas for Commercial Fleets Winterizing Commercial Vehicles: Don't Get Caught Out in the Cold!

Winterizing Commercial Vehicles: Don't Get Caught Out in the Cold! Navigating Your Options: Key Tips For Choosing The Right Commercial Vehicle

Navigating Your Options: Key Tips For Choosing The Right Commercial Vehicle Easing Into a Zero-Emission Commercial Vehicle Fleet: How One Hydrogen Truck Can Start a Revolution

Easing Into a Zero-Emission Commercial Vehicle Fleet: How One Hydrogen Truck Can Start a Revolution Class 2b-3 Commercial Vehicles: How the Industry Can Find the Right Balance Across Supply, Demand, and Emissions Requirements

Class 2b-3 Commercial Vehicles: How the Industry Can Find the Right Balance Across Supply, Demand, and Emissions Requirements